Two notable books have chronicled the history of the

Vibroplex Company:

Two notable books have chronicled the history of the

Vibroplex Company:

A revolution in communication occurred with the development of the telegraph.

However, the early telegraph keys used to send messages caused severe strain

on the telegrapher's wrist - a condition now known as carpal tunnel syndrome.

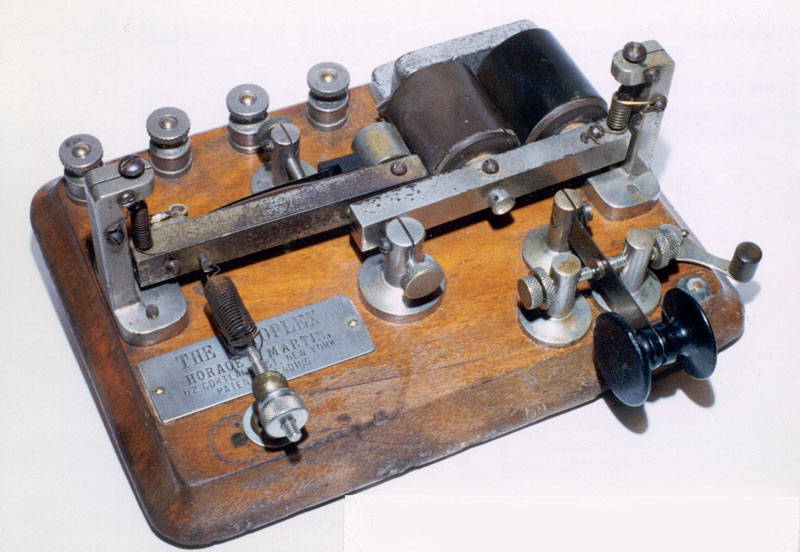

In 1902, inventor Horace G. Martin patented the first in a line of devices

which solved the problem: the Martin Autoplex, an electro-mechanical sending

device which required batteries.

Two years later, Martin went into business with a group of entrepreneurs,

forming the United Electrical Manufacturing Company. It was also in 1904 that

Martin filed his second patent for a new sending device which used a weighted,

vibrating arm and did not require the use of a magnetic coil or batteries.

This device was the basis for the first Vibroplex.

In 1908, the association between Martin and U.E.M. ended when the latter went

out of business. However, J.E.Albright, who began a business catering to the

telephone industry in 1890, began marketing the Vibroplex for Martin. On March

12, 1915, Albright filed a certificate of incorporation in New York for the

Vibroplex Company, Inc. Within a few short years, Vibroplex came to represent

the best of the telegraphic, and later Amateur Radio, industry.

To read John Casale, W2NI's history of Horace G. Martin and Vibroplex,

please connect to the internet and go to:

http://www.telegraph-history.org/horace-g-martin/index.html

Two notable books have chronicled the history of the

Vibroplex Company:

Two notable books have chronicled the history of the

Vibroplex Company:

The Vibroplex Collectors Guide by Tom French - W1IMQ

is in its 3rd Edition.

It is available for sale through Artifax Books: ( www.artifaxbooks.com )

You may click here for a few excerpts:

The History of the Vibroplex Company by Bill Holly - K1BH

was written in 1990.

A very few copies of this book were available from the Vibroplex Company

(www.vibroplex.com) in 2006.

You may click here for a few

excerpts:

This CD link will take you to the

Complete Vibroplex Website as it appeared in 2006

and is reproduced on this CD.

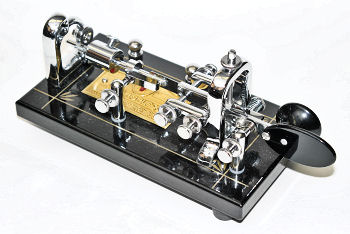

It includes some history and a complete 2006

catalog of Vibroplex keys, parts, and services.

This CD also includes an

Illustrated List of Discontinued Vibroplex Keys.

and a great deal of additional material including some design drawings.

This CD also includes the

"Date your Vibroplex Keys" section of the Vibroplex

Website that presents the research of John Ellwood - WW7P that allows

you to learn the year in which your Vibroplex was made when you know its

serial number.

The following photographs show some of the day-to-day operations of the

company in 2006.

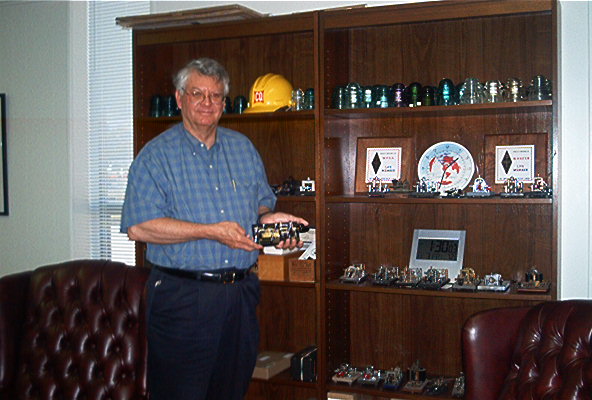

This is Felton "Mitch" Mitchell, W4OA, the President of the

Vibroplex Company.

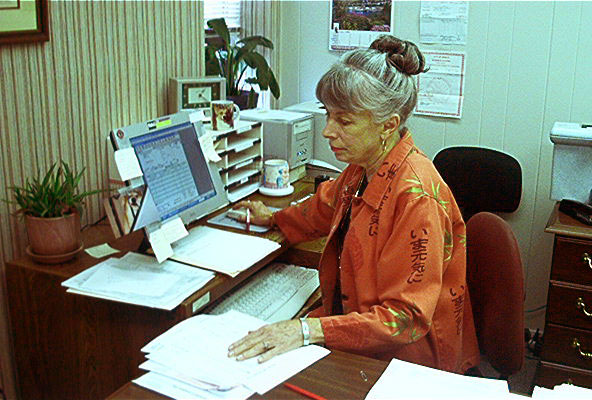

Office Manager, Betsy Hopson, WB4ZYK, keeps up with all orders, email

communications, and customer service. "Vibroplex prides itself on our

customer service. Talking with the customers is my favorite part of the job.

You meet the nicest folks, many from overseas, and make friends for life. It

is especially nice to meet someone at a hamfest that you have been talking to

for years!"

Maura Durant's job is to keep up with all the inventory and keep

orders flowing to vendors and machinists. "This is a full time job, and it

surely does help me to understand what goes into the making of a key and you

can talk to customers better when you understand the parts."

Joan Turner is shown gathering parts for building keys.

Vibroplex has nearly 400 parts in stock. Many parts are still available for

obsolete keys. "Most parts are made by our machinist, Kevin Mills, while others

are subcontracted. We also subcontract plastic fabrication, chroming and

powder coating. Vibroplex is very fortunate to have Kevin Mills as our head

machinist. He is a brilliant problem solver and attends to details and

accuracy in all of his work."

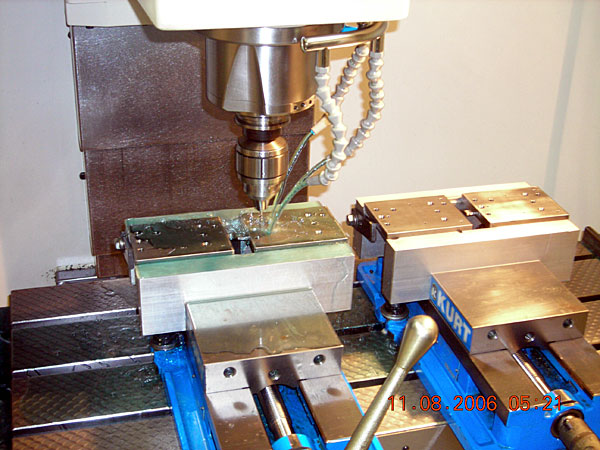

This is machinist Kevin Mills standing in front of the computer controlled

milling machine:

This is a front view of the FADAL Model VMC15XT Computer Controlled

Vertical Milling Center:

These are damper arms, Original levers, and yokes waiting for machining:

These are Code Warrior Jr. top parts cut and ready for machining in the

computer controlled milling machine:

Machining Vibrokeyer bases with the computer controlled milling machine:

This is a view of the 21 station tool turret in the computer controlled

milling machine:

The computer controlled milling machine performing an automatic

tool change:

Vibrokeyer Bases being drilled:

This is the radius tool rounding the tops of Vibrokeyer bases:

Manual mill facing of the tops of Original bases in preparation for

chroming:

A closer view of the manual mill facing of the tops of Original bases

in preparation for chroming:

Iambic, Vibrokeyer, Hand Key, and Original bases ready for chroming:

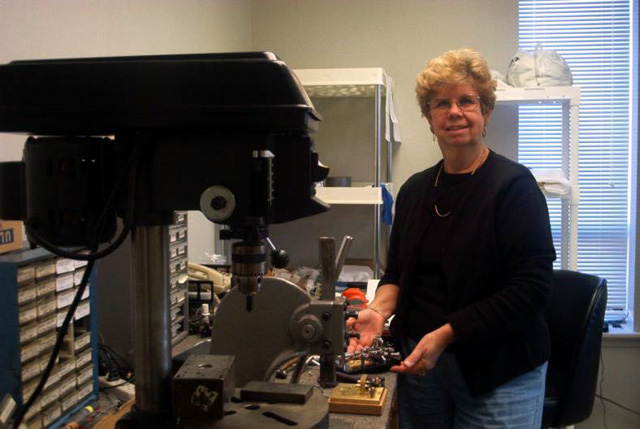

Drill Presses and the special fixture that is used for making

Original levers:

A closer view of the special fixture that is used for making

Original levers:

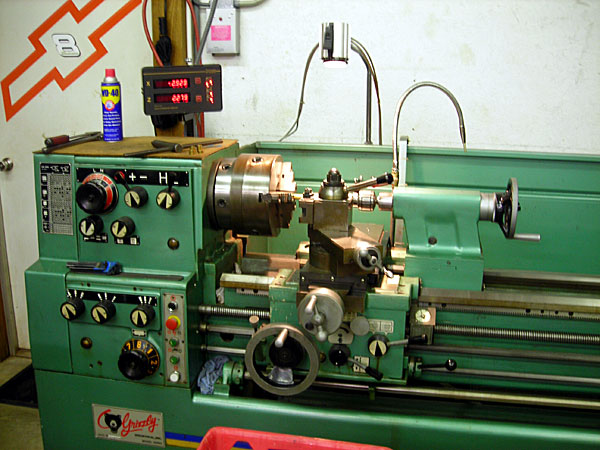

The 18 X 60 Lathe ready to begin making speed weights:

The 18 X 60 Lathe in the process of making speed weights:

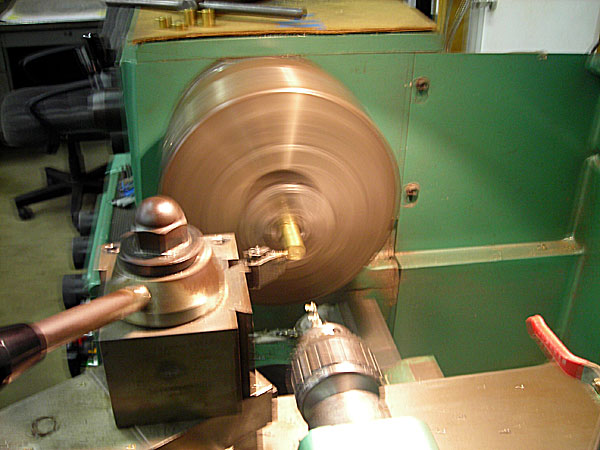

The miniature lathe that is used for making trunion pins and other

small parts:

Dot contact springs being formed by heat and quenched in an oil

bath:

Most of the components of the keys are assembled in advance to speed

the key making process. Liz Fearn puts together the mainframes for all

of the key models. The lever arms, contact posts, and damper assemblies

are all assembled in advance.

All Vibroplex keys are assembled by Joan and Liz. They may be put together

one at a time or in groups of five to 10 at a time. They make about

10 - 20 keys a day. Vibroplex offers customizing, left

handed keys and upgrades that include jeweled parts.

This is production manager Joan Turner in the Assembly Room.

Liz Fearn makes sure that each key is properly packed for shipment.

Vibroplex uses a special key insert and key box to secure the keys.

Then they are double-boxed for shipping. Liz says "We have found that

no matter how carefully an order is packed, the key may still be treated

like a bowling ball by the carrier. We stand by our customers to help

resolve any damage problems. That is why we strongly suggest that

customers keep the original key box in case they have to ship the

key in the future."

Maura checks keys in stock for shipping.

Maura says "We make every effort to keep a quantity of each model of key

in stock for shipping so that orders may be filled immediately. Sometimes,

however, back orders for parts delay our ability to ship a key despite our

best efforts."

This is Betsy Hopson, WB4ZYK, the office manager and refurbisher evaluating

keys that have been sent in for refurbishing. "Our philosophy is not to do

anything drastic to a key that would affect the age value and integrity of the

key. That is why we refurbish rather that restore old keys. The biggest

challenge to date has been several Hurricane Katrina keys that sat in salt

water for days. In that case the bases had to be replaced, but the top parts

were cleaned and allowed to show the corrosion spots as a reminder of what the

key and owner had experienced. I also have a great time with an old key like

the Model "X". Nothing is done to this key except for a good cleaning. Since

each part is cleaned individually, it is fun finding ways to keep track of the

parts and get them back together correctly!!" Betsy refurbishes about 40

keys a year.

This is the building that houses the Vibroplex Company in Mobile, Alabama in

2006.

Tom Perera

Ph. D. - W1TP

Internet On-Line Telegraph & Scientific Instrument Museum:

Vibroplex Manufacturing Facilities in 2006:

The company website: http://www.vibroplex.com always

contains the very latest catalog of their telegraph keys, parts and repair

services, and related material.

He is shown with his telegraph key collection. He is holding the new 100th.

Anniversary Vibroplex Original.

Each key is assembled "lovingly" by hand.

Then it is tested before shipping.

Professor Emeritus: Montclair State University

(I receive over 200 spam messages daily.

To help me avoid them, I ask you to type my email address as

follows with no spaces between words:)

http://w1tp.com

or:

http://www.chss.montclair.edu/~pererat/telegrap.htm

Internet ENIGMA Museum:

http://w1tp.com/enigma